The floating ball valve vs the trunnion mounted ball valve

‘’Floating ball’’ and ‘’trunnion ball’’ are concepts which are used generally. But what are the exact difference between these two designs and when to use which one?

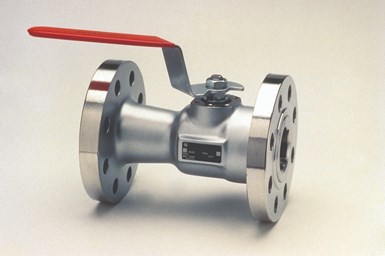

The most important difference between these two design is the construction of the ball and the way in which it is assembled inside the valve body. A trunnion ball is attached and centred inside the valve body through both a top shaft -the valve stem- and a bottom shaft – the trunnion. A floating ball is attached to the valve body only through the valve stem. As a result, the floating ball ‘’floats’’ in the valve seats.

In a floating ball design the ball is pushed against the downstream seat by the in-line pressure, resulting in tightness. When operated from closed to open position, the ball is to be rotated against both the in-line pressure (∆p) and the friction of the seats. In other words: the torque needed to operate the valve is created by both in-line pressure and the nature of the valve seats. The amount of torque required increases significantly when operating pressure (∆p) and/or valve size increase, and/or whenever the nature of the seat is made more robust. The latter applies in case of a metal seated valve design.

In a trunnion design, the ball is inserted in a central bottom shaft which is called the trunnion. The ball is fixed between the stem and the trunnion, which inclines that the ball is not floating but fixed and centred. The inline pressure presses the seats against the ball, causing the tightness. This inclines that during operation, the ball does not have to be rotated against the in-line pressure (∆p) and the valve seats, but that is solely needs to be rotated against the pressure of the seats.

As a result, the required torque of a trunnion mounted ball valve is generally lower than the torque required of a comparable floating ball valve. For example: a DN200 metal-seated floating ball valve would require a significantly larger actuator than a DN200 comparable trunnion valve, leading to significantly lower costs of the overall package. Also, in general the trunnion seat design offers higher stability which makes it more suitable for extreme conditions and especially varying pressure levels.

So, the trunnion-mounted ball valve is more suitable for high pressure applications and bigger dimensions compared to the floating ball. Another advantage of the trunnion design vis-à-vis the floating design is the fact that a trunnion generally is included with a drain or bleed connection, making it suitable to function as a dual safe device. Furthermore, it functions as an relief valve automatically whenever the pressure in the central cavity is higher than the spring force of the seats. When this happens, the seat springs relieve automatically in order to drain the excess pressure back into the main line. Because of these reasons, the trunnion is commonly used in offshore- & oil & gas applications, where extreme conditions pose the standard.

Off course, a large disadvantage of the trunnion compared to the floating design is associated with its costs; which are significantly bigger. Because of these costs, trunnions are used solely when they have to be used.

Our specialist happily assist you in advising the right ball valve design for your application.